Dolomite lumps powder

Price 40 USD ($)/ Ton

MOQ : 100 Tons

Dolomite lumps powder Specification

- Purity

- 90-98%

- Uses

- Soil conditioner, steel manufacturing, water treatment, glass industries, paint industries

- Molar Mass

- 184.4 g/mol

- Molecular Formula

- CaMg(CO3)2

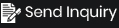

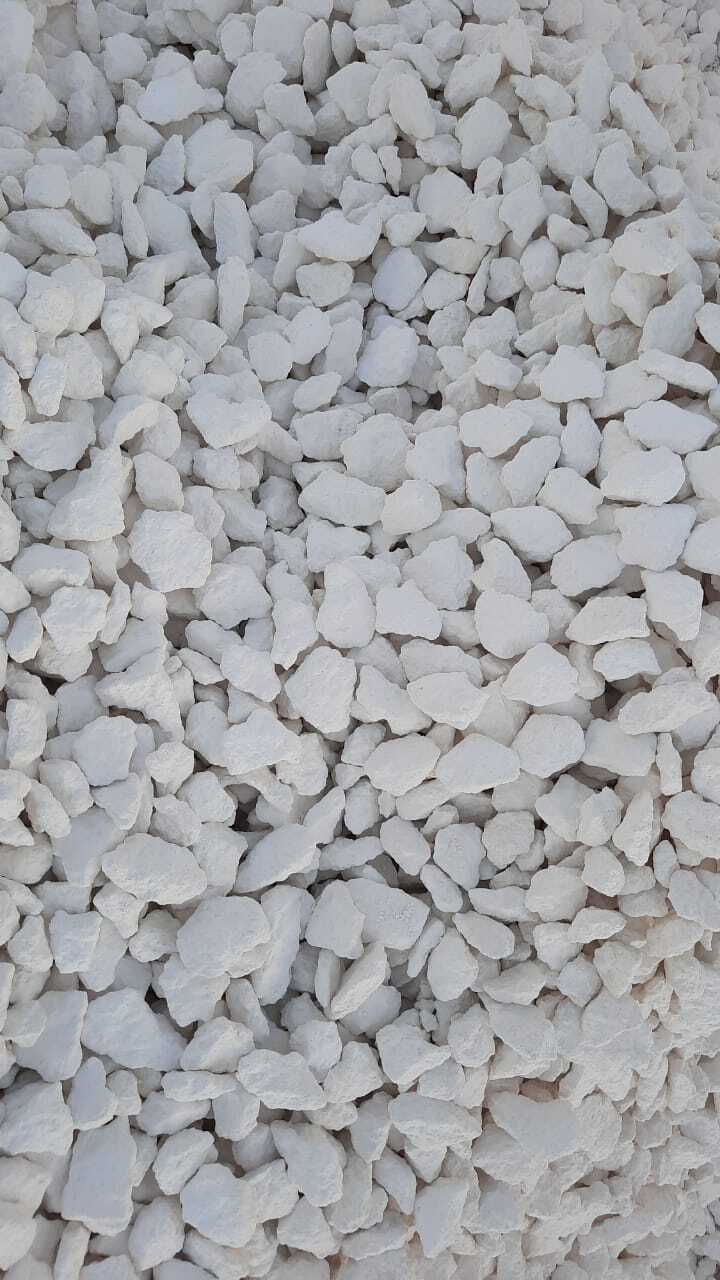

- Appearance

- White to off-white powder or lumps

- Packaging Type

- HDPE bags, Jumbo bags

- Soluble

- In dilute acids

- Melting Point

- 2572C

- Density

- 2.9 Gram per cubic centimeter(g/cm3)

- Physical State

- Powder or lumps

- Product Type

- Hydraulic Lime

- Material

- dolomite

- Type

- dolomite

- Application

- Agriculture

- Size

- granules or other sizes

- Grain Size Options

- Available in various mesh sizes (100-500 mesh)

- Whiteness

- 95%

- Friability

- Low

- Hardness (Mohs scale)

- 3.5 4

- Brightness

- up to 98%

- Oil Absorption

- 21-25 ml/100g

- pH Value

- 8.5 9.5

- Bulk Density

- 900-950 kg/m

- Moisture Content

- <1%

Dolomite lumps powder Trade Information

- Minimum Order Quantity

- 100 Tons

- FOB Port

- sokhna port egypt

- Supply Ability

- 2000 Tons Per Month

- Delivery Time

- 3 Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- 50 kg pp bags or loose in container

- Main Export Market(s)

- Middle East, Asia, Africa

- Main Domestic Market

- All India

- Certifications

- iso

About Dolomite lumps powder

Dolomite lump is well known for its multipurpose roles. It is required to produce glass, refractory materials and fertilizers. In steel plants, this mineral is used as suitable flux needed for purification of molten steel and iron in order to threat their impurities. Lump of dolomite is also required for the production of agricultural lime needed to treat acidic condition of soil and also to enhance its fertility for higher crop yielding rate. Dolomite lump has significant role in construction arena where it is required to build highway, road and concrete structures. It is used as an essential ingredient for producing cement and asphalt.

Exceptional Quality and Purity

Our dolomite lumps and powder stand out for their remarkable brightness, high purity (9098%), and low moisture content. Carefully processed to minimize friability and maximize stability, these products meet stringent industry standards. The bright, white to off-white appearance and controlled grain size options ensure suitability for specialized applications ranging from agriculture to manufacturing.

Tailored for Versatile Applications

With a range of mesh sizes (100500), dolomite powder and lumps are adaptable for various industries. In agriculture, they enhance soil health; in steel and glass manufacturing, they serve as essential flux and raw materials. The consistent physical and chemical properties, including high density and oil absorption capacity, make this product invaluable to diverse sectors.

FAQs of Dolomite lumps powder:

Q: What are the main applications of dolomite lumps powder?

A: Dolomite lumps powder is primarily used as a soil conditioner in agriculture, a flux in steel manufacturing, and an ingredient in water treatment, glass, and paint industries. Its high purity and chemical stability make it a versatile mineral for industrial and agricultural uses.Q: How is dolomite powder produced and processed for different mesh sizes?

A: Dolomite is mined, cleaned, and then crushed or ground into various grain sizes, typically ranging from 100 to 500 mesh. The powder is thoroughly screened to achieve uniform particle distribution and minimal friability, ensuring suitability for diverse applications.Q: When should dolomite be applied as a soil conditioner?

A: Dolomite should be applied before or during soil preparation to help neutralize acidity and provide essential calcium and magnesium. The timing can vary depending on crop cycles and soil analysis, but it is often best used prior to planting or in the off-season for long-term soil improvement.Q: Where does your dolomite product originate and how is it packaged?

A: Our dolomite lumps and powder are sourced from select mineral reserves in India and processed to meet high purity standards. The product is supplied worldwide in durable HDPE or jumbo bags to ensure safe transportation and storage.Q: What are the benefits of using high-brightness dolomite powder in industrial applications?

A: High-brightness dolomite powder enhances the optical qualities and whiteness of finished products in paints, glass, and ceramics. Its controlled moisture, high density, and chemical purity also contribute to improved efficiency and quality across industrial processes.Q: Is your dolomite powder suitable for export and large-scale supply?

A: Yes, as a manufacturer, exporter, and supplier, we offer dolomite in consistent quality, with customizable quantity and packaging options. Our robust distribution network supports timely delivery for bulk orders domestically and internationally.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

|

CHEM SOURCE EGYPT

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry